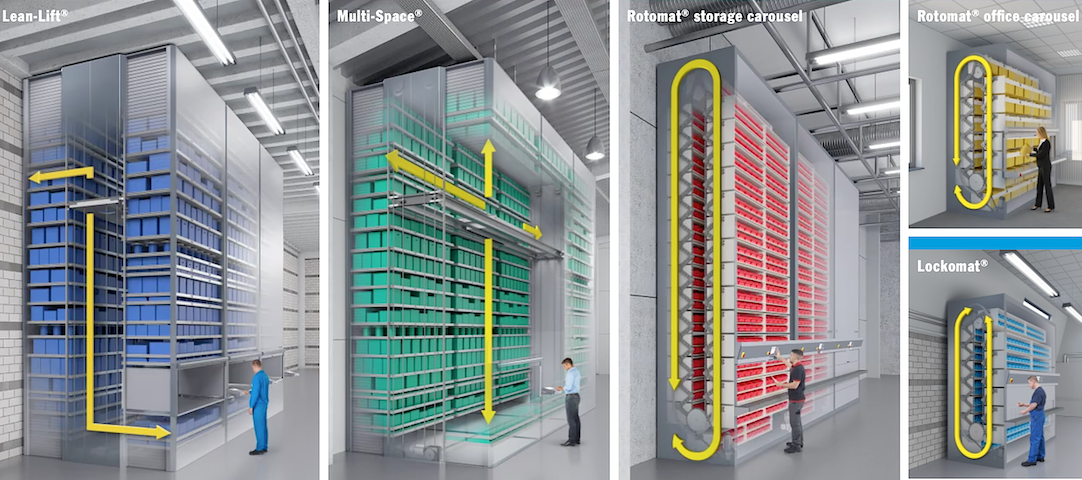

ASRS Vertical Storage Units (VSUs)/Carousels

Vertical Storage Units

Vertical storage units take advantage of previously unused vertical space. Companies that have replaced conventional racks and shelving with automated systems report that they have saved as much as 75% of the floor space formerly devoted to storage.

Installing an automated system may even eliminate the need to expand the facility or move to a larger building. These systems generally require only a modest investment. Automated storage systems typically pay for themselves in about two years.

- Reduce storage footprint by utilizing vertical space

- Can have multi-floor, multi-room, multi-station access points

- Ergonomic – “goods to user” instead of “user to goods”

- High density, high-performance

- Enhanced safety

- Advanced technology increases efficiency and reduces errors

- Secured Storage – restricted access, locking compartments

- Virtually limitless in what can be stored

- Controlled environments

- Bulky, oversized goods or heavy duty goods (from hundreds to thousands of pounds)

- Can be adapted for individuals with special needs

Controlled Access

Automated systems enhance security, a big plus for companies handling valuable, dangerous, or controlled items. High security features can be built in and programmed, limiting access and creating an audit trail of who handled each item and when.

- Medical instruments

- Pharmaceuticals

- Highly concentrated liquids

- Fiber optics

- Precision metals

- Precious gemstones

- Precious materials

- Machined parts

- Expensive tooling

- Armory

Controlled Environments

Controlled environment VSUs are controlled by tight tolerances and offer advantages for items with special requirements such as sterile or ESD.

- Ventilation

- Dust

- Light

- Air replenishment

- Temperatures from -4° to 140° F (or) –20° to +60° C

Applications for Disabled

ADA compliance is a necessity. It is important to enable productive workers to perform their work regardless of physical limitations.

Hänel VSU applications can be customized for individuals with special needs, i.e., limited mobility, wheelchair use, and visual impairment.

- Elongated mounts

- Special gripper arms

- Braille input devices

- Text-to-speech function

- Ergonomic design for unobstructed access while standing, sitting, or in a wheelchair

Bed Lifts

Unused beds can fill hospital corridors creating a hazard. So called “hallway beds” create clutter that violates the NFPA 101® Life Safety Code®, as well as JCAHO standards for the storage of hospital beds.

These violations could lead to fines or worse, the loss of accreditation.

Bed lifts store beds in a vertical arrangement. Units load either from the side or the end, depending on the model and accommodate a variety of hospital beds.

- Stow up to five beds in the footprint of a single bed

- Beds are stored in LIFO (last in first out) fashion

- Standard (27” vertical pitch, 600 lb. capacity)

- Extra capacity (33” vertical pitch, 900 lb. capacity)

- Narrow width ( 31.5”) for narrower profile beds, stretchers, operating tables

- Cribs (up to 600 lb. capacity)

Resources

Articles from Hänel

- The Importance of Reclaiming Floor Space Using Automated Vertical Storage

- Improving Inventory Accuracy with Automated Vertical Storage

Videos