- Design new lab for testing of custom-designed chemical distillation systems.

- Create workspace able to accommodate multiple people working with instruments, equipment, and a fume hood.

- Required utility services including electric, plumbing, and mechanical HVAC be incorporated into the design.

- Easy to clean, durable worksurfaces were a priority.

- Project needed a budget-conscious lab designer, able to deliver robust casework, fume hood, and worksurfaces.

- Early discussions with team working in the lab kept focus on important features including aesthetics, feel, and functionality.

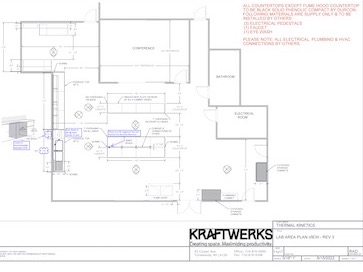

- Strategized lab layout, taking into consideration number of staff, collaboration, equipment and fume hood placement, aisle space, storage, and flow of work to ensure a flexible and functional design was in place.

- Determined modular drawers were preferred; organization and flexibility were required to size an infinite number of compartments for parts, samples, and glassware.

- Specification data and multiple worksurface samples were provided for testing with commonly used chemicals.

- Several concept layouts with options were presented for evaluation.

- Created an aesthetically beautiful, world class lab that was flexible, high functioning, and met all specifications and requirements of client.

- Lab layout improved workflow efficiency with accessible, abundant storage and ample space for staff movement and collaboration, cleaning, maintenance, and safety.

- Selected vendor with a long and proven history of providing high-quality, modular units, suitable for storing a variety of instruments and equipment, which could easily be reconfigured for future needs and growth.

- Pre-testing of sample worksurfaces confirmed the viability of a less expensive worksurface option, saving cost.

- Color selection was matched to company colors.

- Through value engineering, working close with our suppliers, the lab was installed on time and within budget.